The sustainability turn of the Fab Lab Network, Anastasia Pistofidou reflects on the biomaterials community within the Fablab movement (2/2)

Published 4 July 2022 by Maya Minder

On June 6-11, Fabricademy Bootcamp was held at the Fablab Onl’Fait in Geneva. Anastasia Pistofidou reflects on the biomaterials community within the Fablab movement. Second part of our interview.

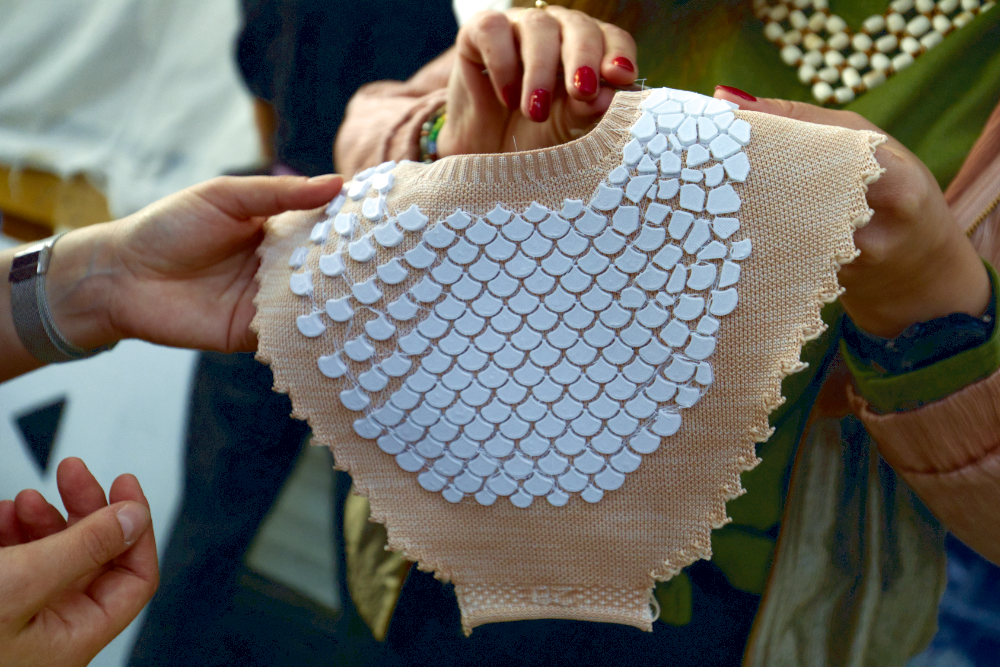

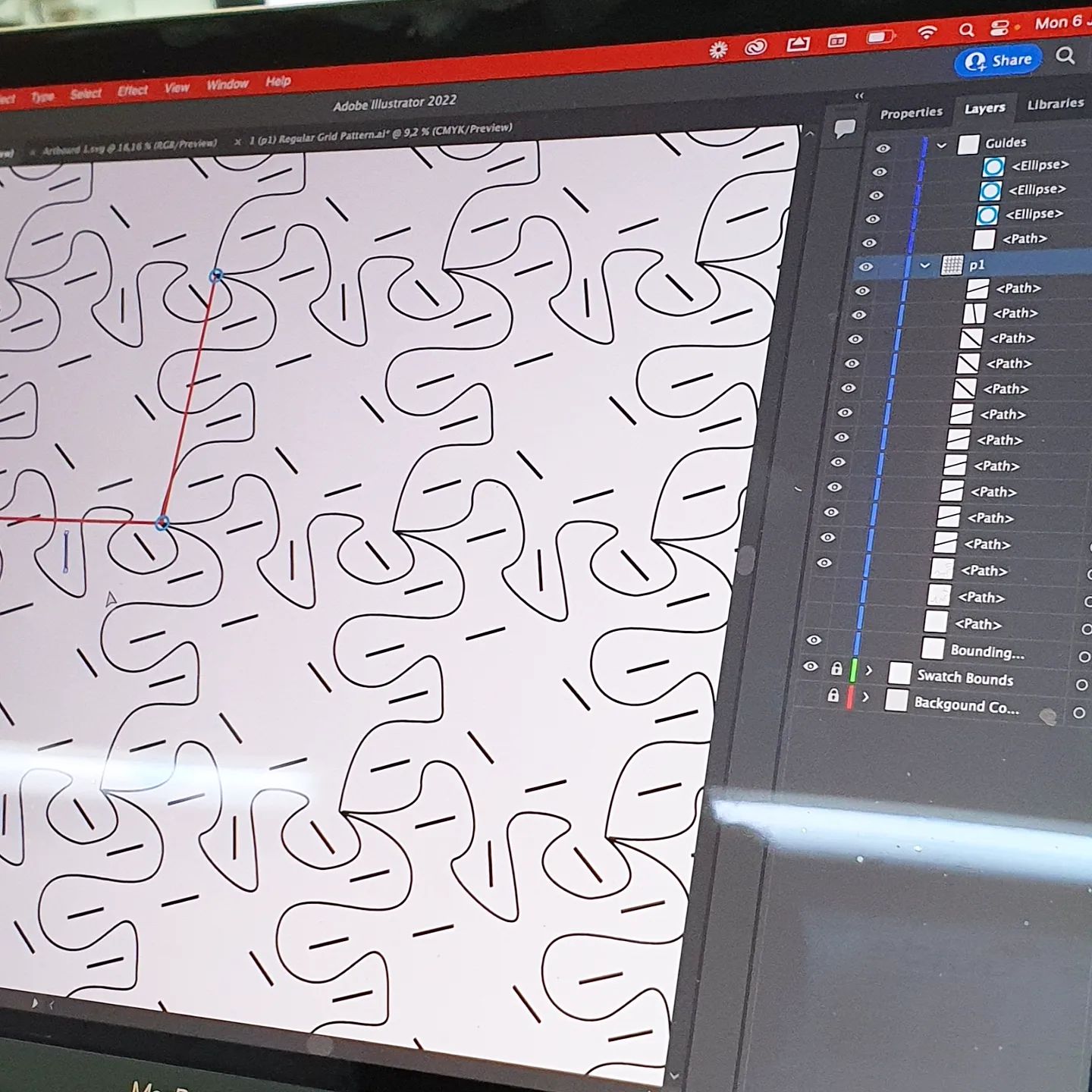

Fabricademy‘s founder, Anastasia Pistofidou, cofounder of Fablab Textiles and research leader at IAAC, Fab Lab Barcelona, together with pioneers of digital fabrication and biodesign, including Cecilia Raspanti co-founder of Fabricademy and of TextileLab Amsterdam at Waag (Nl), Zoe Romano (It), Aldo Solazzo from Noumena (Es), Liza Stark (US), Varvara and Mar (Es), Katia Vega from UC Davis (US), Adriana Cabrera from Matric (De), Oscar Tomico from Elisava (Es) and other experts to build a movement within the Fab Lab Network and beyond. Using open-source digital fabrication tools such as 3D printers and CNC-Lasercutters, as well as bacterial dyes, they reinvented the old crafts of textile material production to tackle sustainability, personal fabrication, new esthetics and practices.

Makery: There is still so much to explore within the research on biomaterials and how to create, optimize, adapt and work with, to produce alternatives to plastics and safe resources. You were one of the first to bring the topic of biodesign into the Fablab world, using paradigms of transparency, open-source access and sharing knowledge. How did you come to start this combination of Fablab and Bioplastic, and where did this inspiration come from?

Anastasia Pistofidou: It is an interesting question, because Fablab itself still is a movement that is very novel, in its early adulthood, just 21 years old, yet with a major impact. I have been involved since 2011. The first distribution of the Fab Academy, How to Make Almost Anything course, founded by Neil Gershenfeld was in 2009. Imagine that Covid made online education an

imperative, but the Fab Academy has pioneered in hybrid learning since 2009… This movement started to mature with time. It is very open, everything can be part of it, there is no franchise, and everything fits.

[The inspiration] came with this maturing stage, reflecting on the practice and realizing you can do almost everything in this lab, which was very powerful. But the question remaining was “Where does the material come from?” We work with this mindset of empowering people to make everything from scratch, with open accessibility on sharing knowledge with open codes and open source tools in a sustainable way. It was a logical consequence to think about where you source your materials from, what trash you produce when prototyping, and how to optimize the system.

There was a convergence of what was happening around us at this time: the inspiration in biomimetic processes, growing materials, bioengineering, with pioneers like Suzanne Lee who published the open source recipes on biocouture. We saw this happening around us, and these practices were something we wanted to put in our agendas and into the way we work.

It was a moment where we met with different like-minded people. Myself, Cecilia and Fiore decided that we wanted to establish an educational program diverging from Fab Academy by using textiles, crafts and fashion as a basis of material research within. This program took form in 2017 and was based on the Fab Academy methodology of distributed education coming out from MIT, from Neil Gershenfeld’s “How to make almost everything”. The Fabricademy is following the same principles of Fab Academy which now forms part of Academany.

Our program started with 13 labs who wanted to join. We have now been running this for 6 years, many people followed the program in the different fablabs and also became instructors, or they were able to professionally succeed being enabled with the technologies learned in Fabricademy.

How has the term digital fabrication changed today compared to when you started?

My introduction to digital fabrication was originally to realize that it is a tool empowering me to design and prototype my ideas quickly. Now I perceive it as a solution for local sustainable manufacturing, resilience and community. But I think the world is still very new to this world of Fab Lab. Ten years ago we were saying we come from Mars; we could say that now we are more normal, but still from the Moon. (laughs)

In 2010 we would receive one phone call every two months from somebody who wants to 3D-print something. In the whole city of Barcelona, there was no other Lab that could offer this tool. In 2022 you have Hubs, an online platform where you have 700 providers of printers and 35 co-working spaces equipped with all of these tools. It’s a big difference.

The percentage of women in this Bootcamp is 95%. Are you deliberately promoting women in tech, or does it have to do with the material itself?

The numbers in Fabricademy are 95% women and 5% men. In global statistics though, if you look at it in the entire Maker, Fablab and network user community, Fabricademy is definitely enriching the network, both in content and by contributing to gender balance.

It was not per se our intention. I think it is very related to role models and the fact that the leaders of the program are both women. I wish there were more men interested in digital craft machines and soft fabrication. The program is not about fashion, it is about textiles in a broader sense. We have participants who are ceramists, anthropologists, biologists, costume designers. Textiles are everywhere, and there are millions of solutions to be found and space to innovate.

Fabricademy also helps create networks. How important is this to you?

It is very important and it is very nice to collaborate with like-minded people. We also try to help the Fabricademy networks by applying for funds. For example, with the European program Shemakes, we were able to create a network connecting Fabricademy to textile and clothing business labs and expanding our impact with learning paths and innovation services. We can now work together for the next few years to develop new research and topics around textile fabrication. We are also diversifying the Fabricademy program to have Fabricademy kids, and more business partners who are keeping the open access premises.

Open source, transparency and open access as keywords. Some people who are not familiar with them, who work within a system based on copyrights and licenses, do not understand the core concept of open source. Since you have worked with this for more than ten years, could you say some final words? Is open-source difficult or promising?

Don’t worry, they will understand in the end, we just need to open the road. It will become mainstream, and it will be the only way. Nowadays – and this is also why inside Fabricademy we question the way we learn and the role and formats of education. So where does the knowledge come from? Wikipedia is open source and it is human-powered for humans, everybody can be a contributor. We want to continue with this model and work with each other.

Fabricademy’s 6th edition starts in mid-September in many locations worldwide, and is currently offering 50% scholarships to attend the program at the Icelandic Textile Research Center.

Read the first part of this interview.