Domingo Club: “We’d like to share fabrication recipes like we share food recipes”

Published 11 September 2021 by la rédaction

Designers Maud Bausier and Antoine Jaunard, co-founders of the Domingo Club in Barcelona, made a tempeh incubator that was awarded at this year’s Distributed Design Awards. This summer, they also participated in the Hyper Global / Hyper Local virtual exchange of the Makersxchange program. Makery first met the duo in Barcelona in July, then caught up with them again in late August.

The Domingo Club is a Barcelona-based designers collective dedicated to fermented food and open source tools, initiated by Belgian designers Maud Bausier and Antoine Jaunard. The bigger idea behind the project is to distribute homemade tempeh production and promote plant-based high-protein foods, via an online platform to share recipes, knowledge and experience.

Makery: What’s the story behind the tempeh incubator?

Maud Bausier: We started this project in April. We are originally from Brussels. We began working together during internships at fablabs last year, me in Amsterdam, and Antoine at the Fab Academy in Barcelona. I was also working a lot at the biolab in Amsterdam, in DIYbio and biohacking, and I discovered how to make projects with mycelium. When I came to Barcelona, I started an internship with the Fab City Hub, and then started a biolab there — I would say it’s more of a biolab kitchen, for things you can easily make in your home. Antoine and I combined our skills to try to make it work. And because the Fab City Hub here in Barcelona had to leave their venue because of the Covid-19 pandemic and move back to the fablab and focus more on online events, we decided to continue by ourselves at home.

Antoine Jaunard: Part of the story is that we discovered tempeh when we were in Amsterdam. We had a small room in our flat that was always warm, so it was very easy to ferment, we made tempeh all the time there. But when we moved to Barcelona, where the flats are not as insulated as in Amsterdam, as is often the case in southern Europe, we didn’t have the constant temperature we wanted. So, with the skills we learned in fablabs, we decided to make the tools we needed to make tempeh all year round. We were hacking our flat in a way, so that we could continue fermenting at home, even without the heating we had before.

Makery: And the biolab in Amsterdam was at the Waag Society?

Maud Bausier: Yes, Lucas Evers is in charge of it. But I was working more with Cecilia Raspanti from the Fabricademy who uses it a lot, and so, with other students and interns we could explore microbes, bacteria, mycelium, and other natural processes.

Makery: How did you come to combine the kitchen and the biolab?

Maud Bausier: At the beginning we thought that a biolab is for biology, bio sciences, for professionals and people educated in biology. But once you’re inside, you realize that you can already start to play with biology using very simple things such as food. That’s why I find the comparison with the kitchen to be interesting. You just need some tools and to apply some recipes.

Makery: What were your first recipes? What kind of ferments did you play with?

Maud Bausier: We started with tempeh production, trying different grains, different recipes. I also did some experiments with mycelium and straw, to see how mycelium can strengthen a woven straw base. We also made kombucha, kefir and did some lacto-fermentation.

Antoine Jaunard: We’re curious about science, how to make it accessible, and to ferment food in order to enhance our local food. We’re vegan, so we look at how to eat more conscientiously, how to get more protein out of our food, and how to share this with others, so that people can also consider changing their food habits. Fermentation is an ancient knowledge that people should share more, and since we are able to make our own tools, we want to make fermentation methods more accessible to others.

Maud Bausier: What’s interesting with fermentation is that it’s a bit out of your control. You do the work, and then you wait for the micro-organisms to develop ferments. It’s nice to see this collaboration with bacteria, where you don’t have control over everything.

Makery: So you have created tools to make fermentation more accessible to people in general, but what are the limits to that?

Antoine Jaunard: Maybe the main limit is the time it takes to nurture your ferments, as we live in a busy society where it can be hard to take time, to observe, to see what happens. We tend to put the Now aside, but the Now is very important in fermentation, and in life in general, of course. That’s something we need to cultivate. Also we need to learn from our mistakes, to not be discouraged and to try again and again. Fermentation can be so much fun and teach us such simple and good things, once we learn to observe.

Maud Bausier: We also want to teach to people that you can easily make stuff by yourself. Like fermented food. But also your own tools. So you can produce your own food and consume differently. Be more resilient. Be more self-sufficient.

Makery: Fermenting food is the most accessible way to enter biology, as you encounter non-visible germs, of which we have such a phobia. Germophobia is such an obsession in our society, where we try to control every surface we touch, it’s all about cleanliness. So the hands-on process of fermenting food makes us realize that there are good bacteria as well.

Maud Bausier: I think this fear about bacteria is rather new. It’s only after the Second World War that we started to clean our food, clean everything, clean the bacteria, because people were living in unsanitary conditions…

Makery: …and because there was a big industrialization process going on, with refrigeration, supermarkets…

Antoine Jaunard: We now realize that we need to go back to old practices that were better for the environment and our bodies, that we need to reintroduce bacteria where they belong.

Makery: Did you decide to introduce fermentation culture through the world of digital fabrication as a way of making it even more accessible?

Maud Bausier: We’d like to share fabrication recipes for the tools we use like we share food recipes — on the Internet, in books, across generations. To apply the same logic we apply to food, thanks to the concept of distributed design, peer-to-peer sharing, with open sources in order to reach more people.

Antoine Jaunard: In the kitchen, everything is open source by default, except maybe for products like Coca-Cola (laughs), but for everything else, there are cookbooks where people share their recipes. But in technology, it’s different. People tend to want to make a profit, to not share the sources (“I’ll show you the product, but not how I made it”). For us, it doesn’t make sense. The whole point of this is to generate/extract money, but if you want to have an impact, if you want to help change the world, what’s the point of keeping things to yourself?

Maud Bausier: And sharing the source doesn’t mean you’re not going to make money, because often people will need your skills as well. People know how to make a pizza, but it doesn’t mean they won’t buy your delicious pizza!

Makery: Not everybody knows what tempeh is and how to make it. What are the specifics of tempeh? Where does it comes from? How do you make it? What is the tradition behind it?

Maud Bausier: Tempeh is an Indonesian product. It’s made out of soy beans and a fungus called rhizopus. This fungus is usually found in hibiscus leaves. If you want to make the tempeh starter, traditionally you put some cooked soy beans in the hibiscus leaf and let the mushroom grow in the soy bean. When you have your tempeh starter, which you can also just order in a powder form like us, you can start to make your tempeh.

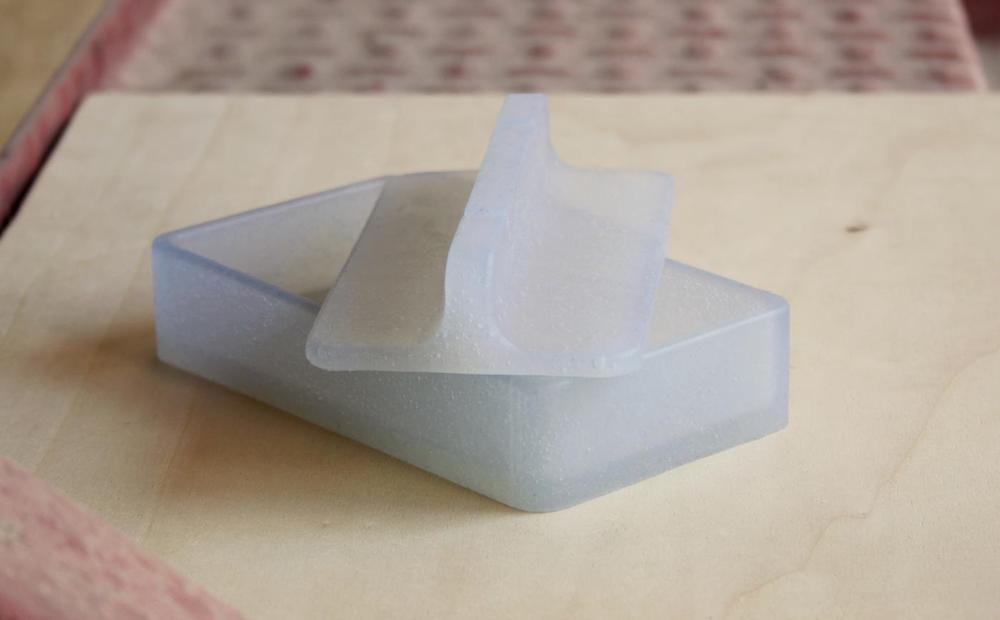

You have to cook the beans, dry them and mix them with a bit of the rhizopus, the tempeh starter, then traditionally you wrap them in banana leaves, and you let the rhizopus grow around the soy beans until it becomes a compact block. In Indonesia you don’t need an incubator to do it, because it’s hot and humid, with a constant temperature, and after 30 hours you have your tempeh. But if you want to do it here, you need to maintain this temperature, so you need an incubator. We also don’t use banana leaves. You can use freezer bags, but we decided to produce our own molds.

Antoine Jaunard: Soybeans are very rich in protein, but if you only eat the soybeans, you will not get all the nutrients. The fermentation process, on the other hand, predigests the soybeans, allowing our bodies to absorb all the protein they contain. This makes tempeh as rich in protein as meat and therefore one of the best vegan alternatives to meat. Tempeh is already widely consumed in Indonesia, and we are trying to introduce it here too (along with many other tempeh projects).

Makery: So you use a heat sensor, a humidity sensor, with Arduino?

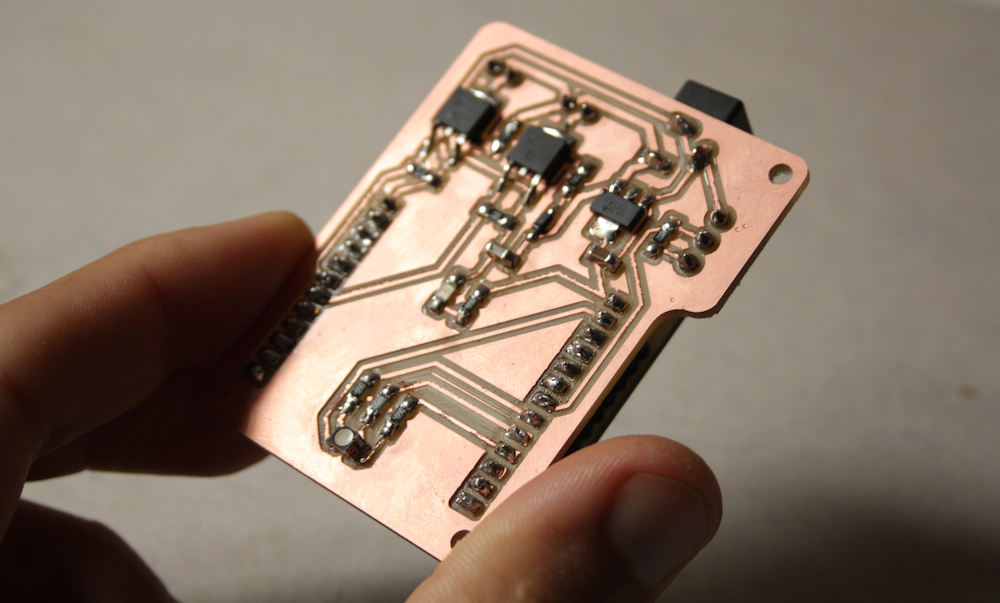

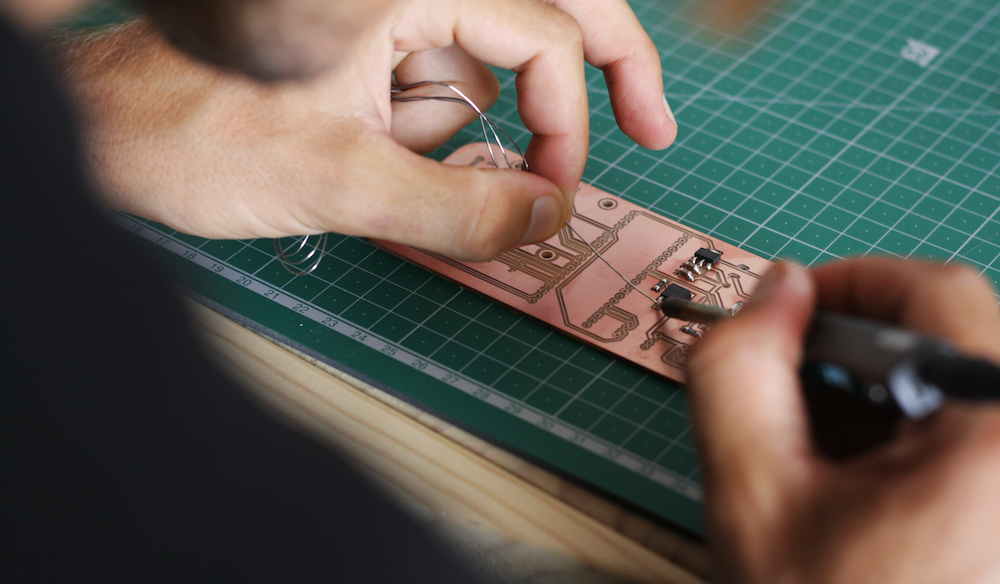

Antoine Jaunard: Inside the incubator we are developing, we use a temperature and humidity sensor to monitor the environment, a heating pad and a fan to regulate the temperature and distribute the heat evenly, a small screen and buttons for the interface and a microcontroller. For the microcontroller we first used a Barduino, an ESP32-based development board designed and produced at Fab Lab Barcelona, but with the new prototype we are using the Raspberry Pico.

The Pico is cheap, about 5 euros, and we can program it with MicroPython for microcontrollers. MicroPython is easier and more accessible than C++ (Arduino) and therefore a good candidate for teaching code to beginners. You don’t need to declare variables, you can code directly without worrying about syntax, it may not be the most efficient, but it is a better choice for our educational purposes.

Makery: Tell us about your virtual exchange in the context of Makersxchange?

Antoine Jaunard: We wondered whether we should do it online or in person, but it made more sense to do it virtually, especially in light of our involvement in distributed design. We work with Valentina Manera in Amsterdam, the one who introduced us to tempeh. We’re doing the Makersxchange with her and we will send our mold to her, then she will test it in her tempeh production, send us feedback, so we can modify and co-design the next version. Then we will teach her how to 3D-print the tempeh molds directly in Amsterdam.

We want to design a new version of our mold, but also to understand clearly how we can distribute our design without us having to explain how to fabricate it. Valentina is a tempeh producer, but with no experience in digital fabrication, so we would like to know how easy or not it is for her to go to a fablab or a makerspace, to use the file and print it. It’s an ongoing discussion, how to distribute 3D-printed design, since in practice it is not very common yet.

Maud Bausier: A few weeks ago, we also entered our tempeh molds in a challenge from WikiFactory and Mayku, and we won a Formbox. I think they are interested in connecting digital fabrication and maker culture to food culture, as they want to find ways to reach out to a larger audience of makers. For us, it is a great opportunity to explore other techniques to make our tempeh molds.

Makery: So how did you come to win a prize at the Distributed Design Awards?

Antoine Jaunard: The Distributed Design Awards celebrate the best responses by designers to the post-industrial design paradigm. They recognize the most innovative, supportive and sustainably designed projects across Europe. They look at projects that take into account distributed design principles, the circular economy, social challenges, etc. We presented our tempeh incubator, which can be entirely fabricated in any fablab or makerspace around the world, promoting plant-based protein production (through tempeh) and observation and collaboration with natural processes. We were honored to win first prize. We are very happy about this, as it means that our project can sustain itself a little longer.

Makery: And now you’ve launched the Domingo Club in Barcelona?

Maud Bausier: We want to invite everybody to ferment and use and modify the tools we make. So we thought that it would be a good idea to start a fermentation club gathering lot of people doing the same thing, in order to share tips and information. Also just to be among peers, to be part of the same driving force. We learn a lot from the experiences and the discussions we have with people. Now we want to share this knowledge with others, while we also continue to learn.

Antoine Jaunard: The main use of our incubator is to make tempeh, but there are many other uses for an incubator. With a community we might be able to find other ways to use it, in DIY biology, mushroom-growing, etc. We feel that there is very good energy in Barcelona, even if the funds are a little bit lacking, a bit opposite to what we found in Amsterdam or Brussels. But the energy here pushes us to be more imaginative. I hope that the club will be a place to share this energy and reach a state of symbiosis where we give as much as we receive.

Makery: Are there good groups of fermenters in Barcelona?

Antoine Jaunard: Not really groups of fermenters, but several known fermenters: @macondiments – miso, koji, amazake / @vacka42 – vegan cheese / @microorganismesorg – kimchi, sauerkraut / @lovferments – kombucha / and others!

Reflecting on the Makersxhange experience at the end of August

Makery: Did you make good progress this summer? How did the virtual exchange go?

Antoine Jaunard: The summer is hot in Barcelona, which invites us to slow down, to look at where we are, to be in a state of observing more than doing. We took the time to go for a long walk in nature following the paths of Santiago de Compostella, to get out of our comfort zone and recharge our batteries. I think this is very important to keep a good work/life balance.

Maud Bausier: That said, we are making good progress with our tempeh incubator! We are currently very close to reaching our MVP (minimum viable product), which we can then start to distribute. We are very excited to get out of the development phase and get more into the material, into the exchange with people.

Antoine Jaunard: And for the Makersxhange with Valentina from MyVeganFam, the exchange is going very well so far. She advises us on the materials and properties that our molds should have. We have tested our 3D-printed molds, and now we are testing to make them in silicon, to get a more professional version. Molding and casting is fun! It always amazes me how much can be done quickly with the tools of a fablab.

In closing: Thank you Makery – Ewen and Maya – we are very glad to have met you in our studio in Barcelona. Come back whenever you want for more “fermented discussions” 🙂

Domingo Club

The Distributed Design Awards

Hyper Global / Hyper Local at Makersxchange