Tokyo Olympics Pioneers Pellet-Printed Podiums

Published 1 August 2021 by Cherise Fong

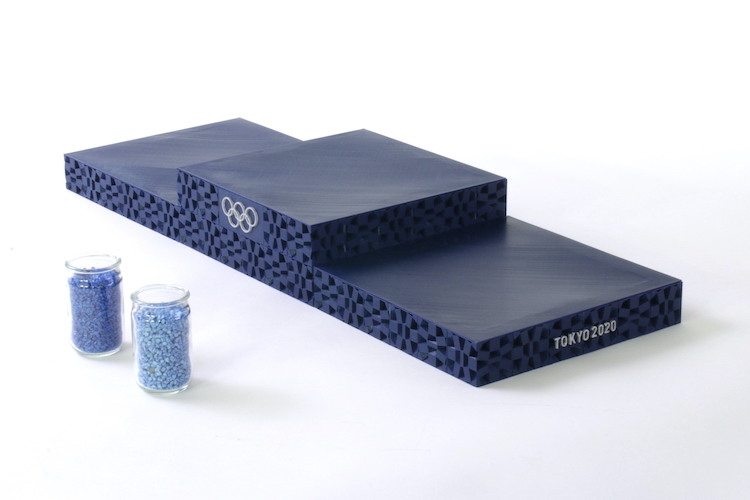

It all started with 24.5 tons of used household plastics—collected, sorted, shredded, pelletized. Once all the parts were streamlined into place, 7,000 indigo patterned panels used to assemble one hundred Olympic podiums were 3D-printed in just 20 days.

Tokyo, from our correspondent

If public opposition to hosting the Tokyo 2020 Olympic Games during a pandemic surge in the Japanese capital still looms, it wasn’t always this way. In the few years leading up to the event, many residents were enthusiastic about contributing their used plastics and e-waste to be upcycled into valuable Olympic pieces. Now that the Games are well underway, an ambitious quest to spotlight the use of recycled and sustainable materials has largely cleared its hurdles.

The Athletes’ Village Plaza is constructed with lumber borrowed from 63 local governments across Japan, from Hokkaido to Kyushu. All 18,000 bed frames in the Athletes’ Village are made of cardboard, with custom mattresses engineered from thermoplastic fibers that can be washed, reused and recycled. The Olympic torches incorporate aluminum recycled from temporary housing units used after the 2011 tsunami that devastated the coastal Tohoku region. Every one of the Olympic medals is molded entirely from melted gold, silver and bronze extracted from 79,000 tons of donated smartphones and other discarded electronics collected across Japan over two years… And all one hundred Olympic podiums were 3D-printed using pellets made from two dozen tons of shredded household plastic bottles collected over nine months.

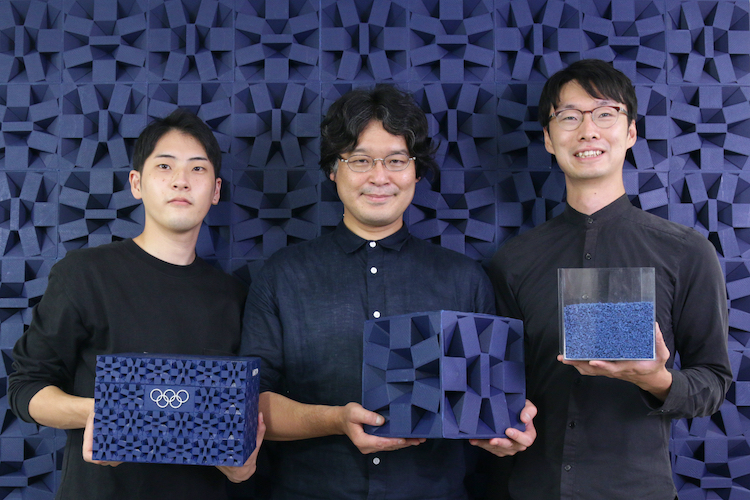

Looking back on this last Herculean task more than a year later, Keio University professor Hiroya Tanaka (whom we first met several years ago as the founding father of fablabs in Japan) breathes a sigh of relief. The man who orchestrated the months-long 3D-printed podium plan spoke with me at his off-campus lab in Yokohama.

3D-printed podiums from upcycled pellets

The story of the podium began with Asao Tokoro’s design of the Tokyo 2020 Olympic emblem, which was directly inspired by the traditional Japanese “harmonious checkered pattern” (組市松紋, kumi ichimatsu mon). When conceiving the Olympic podium, the designer reframed the diverse rectangles within the circular emblem into a new concept based on aggregated cubes made of recycled plastic.

As Professor Tanaka’s lab was commissioned to find “the best way to build a bridge between the design and the material”, he made a bold suggestion: Why not 3D-print the entire final podiums? As the Olympic Committee members considered the quality and unavoidable time contraints in mass producing one hundred full-size podiums, they were skeptical.

At the time, “Asao was the only guy who believed in me,” Tanaka recalls, laughing. His team worked with the designer to adapt the 2D pattern into a mathematical 3D image. Then they optimized the podium’s cubic design into an assemblage of 70 individual square panels, each one incorporating the many different depths and angles inspired by the original emblem.

By then, Olympic public donation campaigns had collected 24.5 tons of household plastic waste—mostly in the form of sturdy shampoo, laundry detergent and kitchen cleaner bottles—from supermarkets, factories and elementary schools throughout Japan.

The first challenge was to sort all this raw material, which varied widely in quality and color. “Recycled materials warp easily, which makes them difficult to work with,” says Tanaka. But over three months, volunteers helped them sort the materials so that they could be shredded efficiently into flakes of similar quality and colors. The flakes were then mechanically “pelletized” into uniform plastic pellets and mixed with natural indigo pigment pellets that could all be fed directly into a specialized 3D printer, without the need to melt them into filament.

Professor Tanaka’s student Soya Eguchi, in charge of G-code programming, and Project Assistant Professor Ryohei Yuasa, in charge of material production, then spent two months refining the hour-long printing process of a single panel in order to achieve the best quality. They modified speed, temperature, angles, order, etc., making about a hundred prints until they were finally satisfied with their prototype. Then they passed the G-code on to S-lab, a Japanese company specialized in pellet-based 3D printers, which developed a custom machine with 12 arrays in order to print all 7,000 panels for the hundred podiums in just 20 days. That was in May 2020.

Post-Olympic plans beyond Tokyo 2021

What will happen to the podiums once the Games are over?

“That’s a very important question,” says Tanaka. One possibility is to reassemble the panels into cubes and give them to Olympic and Paralympic participant countries as souvenirs. Another option is to redistribute the podiums to all the participating elementary schools in Japan. His dream, he confides, is to pass the baton of this successful experience of 3D printing with recycled materials to the Paris 2024 Olympic Games.

“The Olympics are a very special event, so people want to contribute,” Tanaka explains. “Hopefully our next big opportunity in Japan will be World Expo 2025 in Osaka.

“This is a symbolic project of the circular economy and recycled systems. Plastic is a symbol of cheap, uniform mass-produced synthetic material. It was invented over a hundred years ago, so this project is a symbol of the last century! We can make the transition from low-value plastics to paper, for example, but there are lots of higher-value plastics that are already present in society, so we need to collect them and recycle them into new shapes.”

“My research is on how to combine recycled materials with 3D printing, how to use old materials for new purposes. The key is how to mix old materials with other materials like concrete, asphalt and wood. Fortunately many companies are interested in sustainability, but most don’t understand the power of additive manufacturing technologies as a core driving force for making the transition from mass industry to the circular economy, from linear production systems to circular production systems.

“The construction industry is one of the most challenging, because recycled material is more expensive than virgin material. This is a fact. So the biggest challenge is how to make this transition all in one package—economic system, social system, manufacturing system—they’re all related, all connected.”

At 46 years old, Professor Tanaka remains optimistic. He believes this ecological reform can be achieved within the next ten years, as the world strives to meet the United Nations’ sustainable development goals (SDGs) by 2030.

Meanwhile, he is open to collaborations with Paris for the 2024 Olympic Games!

More on Professor Hiroya Tanaka’s Keio University Social Fabrication Lab and Digital Manufacturing and Design Research Center for Emergent Circularity