Column of a material maker (28)

Published 24 April 2018 by Caroline Grellier

In order to upcycle by-products of the cotton industry in Benin, our maker is visiting factories, cotton farmers, getting familiar with the machines, experimenting in the lab… And counting on co-creation.

Cotonou, correspondence (text and pictures)

In Benin, heat, heat and hard work! It’s been nearly two months since I arrived at Potemat, a research laboratory in local materials on the campus of Abomey-Calavi University. I am undertaking an internship under the direction of the teacher Chakirou Akanho Toukourou, to validate a master’s degree in society design innovation at the university of Nîmes (south of France). My mission consists in supporting a project on upcycling by-products of the cotton industry into local materials.

From Cotonou to Parakou, field survey

In the starting-blocks, immersed in the cotton industry! On the menu of phase 1 of the project: loads of texts and scientific articles to read under a fan to understand the sector, its issues, its history, locate the discarded or undervalued by-products and identify project opportunities.

I reformulated this large analysis work graphically in the form of synthesis posters, understandable by everyone. Three factory sketches and formatting of the different stages allow me to have a clearer vision of the by-products in question.

And to check the data and better grasp this issues of the cotton industry, nothing better than field visits, meeting all the actors, from the cotton field up to the manufacturing factories. I was thus able to satisfy my curiosity for machines…

After several meetings in Cotonou with organizations in charge of backing the development of the sector and supporting cotton farmers, off to Lokossa to pay a visit to the Benin textile company (CBT), the last textile factory in the country.

A post shared by Makery France (@makeryfr) on

While discussing with the chief of production, I completed my diagram and discovered new discarded materials in the sector: sized pieces of yarn for example, or still the exposed areas of the cotton bale that harden in contact with humidity and outdoor air.

I was present at all the stages permitting the production of cotton yarn: threshing, carding, stretching, spindle rail and winding onto a bobbin, then warping, sizing and weaving of the carded cotton. From raw cotton to the carded cotton sent to the Ivory Coast for the printing of the famous wax also called African fabric, renown internationally.

Second step in Bohicon at a crush plant that produces oilcakes (residue from oil extraction) and cotton oil. Wearing a safety helmet, I went through the different transformation areas, from the arrival of the cotton seeds to their treatment.

Here again, by-products are thrown away, considered as waste, although they have true potential. Waste of fiber, husks, husk ash and filtration sediments will be subjected to material exploration. And bingo, in the boot of the car!

Third step further north, a seven-hour drive from Cotonou, near Parakou, to talk to cotton farmers in their fields and gather their potential needs in materials, their difficulties in managing cotton plant stems, their practices, understand their working day.

With my French accent and speech rate, not always easy to make myself understood but you always end up succeeding. Upcycling cotton stems? The subject that divides! Agronomists campaign for going back to the land but grinding and burying, vital to avoid the appearance of parasites, is not available to cotton farmers, for lack of equipment. Furthermore, other studies in India and the US showed the economic relevance of upcycling cotton stems into particle boards. A project was in fact launched in 2015 in the West African sub-region, but has evidently been stopped. Ongoing enquiry…

Finally, key step in the sector: the ginning factory. Where one separates the seeds from the cotton fiber. With the hubbub of the machines, you have to shout to try and ask questions. Here too, for each cleaning of the cotton fiber, residues are discharged outside.

So, I went back to Cotonou loaded with sample bags and full of ideas. An effective study: before going in the field, three by-products had been identified. After the mission, we counted fourteen.

Next? Co-creation workshops to elaborate with several brains the experimentation protocols of material by-products, according to the problems noticed in the field.

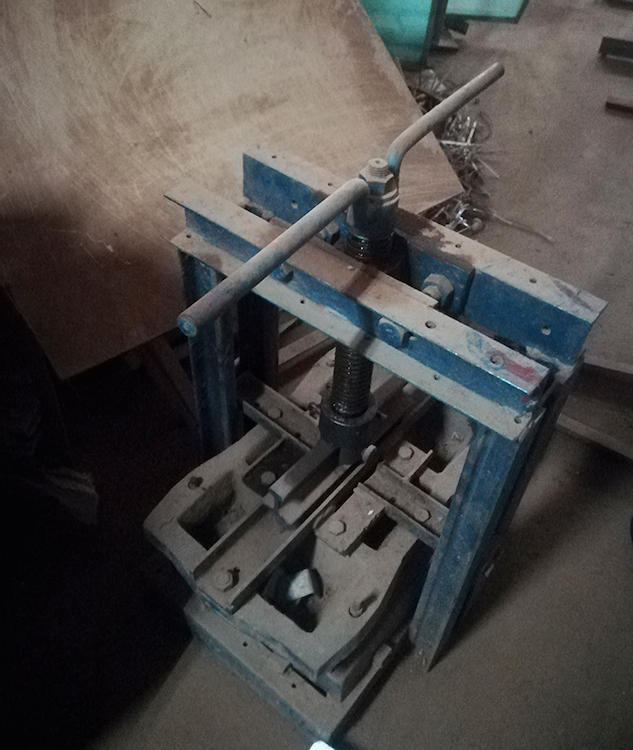

Makers of machines

In parallel, with three students in mechanical engineering at Cotonou, we are thinking about transforming a tile press into a steam press, adapting a grinder for cotton plant stems, and designing a low-cost defibrillating machine to clean and stretch our fiber waste.

Having made the inventory of the food-processing equipment present in the workshop of Epac (Abomey-Calavi engineering school), we thought about and finalized the design plans this week! Screwdrivers and hammers will thus be part of the next column.

See the previous columns of a material maker