Column of a material maker #4

Published 6 April 2015 by Caroline Grellier

The objective for March of La Termatière, Caroline Grellier’s project of viticulture by-products upgrading: define her investment needs. Meaning one month of finance, one-to-ones with Excel spreadsheets, in order to progress from DIY sampling to mass production.

A barter of skills between designer and researcher?

Since researchers are a very sought-after specimen, who juggle between their work and fundraising to pursue their work, the collaboration with the two research units of the National Institute for Agronomical Research (Inra) accompanying me will take a little bit of time to set up. Money, always money… I thought I could go beyond it with my material maker approach, but when it comes to pressing buttons on machines that cost several thousand euros, there is no more talk about DIY. Understandably.

Since I do not currently have a 5 figure cheque to sign, we are discussing which form could take this designer-researcher collaboration, unprecedented for Inra, with the hobbyhorse that unites us: the development of bio-sourced materials. Different options are being examined to define together a win-win partnership concerning mutual exchanges. And I am happy with this course of action by “bartering of skills”.

Meeting the pros of grinding

THE meeting of the month, that I have been ready and waiting for, was a feast for my eyes. I was able to visit the platforms of the Inra IATE unit, specialised in the upgrading of vegetable raw materials in the form of food, energy, biomaterials or biomolecules.

Having spotted the machines I will need (extruder, presses, dryers, mixers), I discovered dozens of ways of grinding materials: a presser roller that shakes and flattens the mixture against the side of the cylinder like a high-performance cheese grater, separation of micro-powders by electrolysis, demijohns of nitrogen, pipes here, sieves there, a true amusement park for my little designer hands: truly inspiring machines.

My challenge? Launch, come September, a first batch of shim-stocks for the transport of wine bottles, made from defibered vine shoots. First sale means first income! And understanding one’s company accounts is a very different ballgame than managing one’s bank account…I therefore had to immerse myself for a few weeks in funding plans, estimated expenditure and profit and loss accounts, compulsory pieces of information to compile in the dossiers of the contests I take part in.

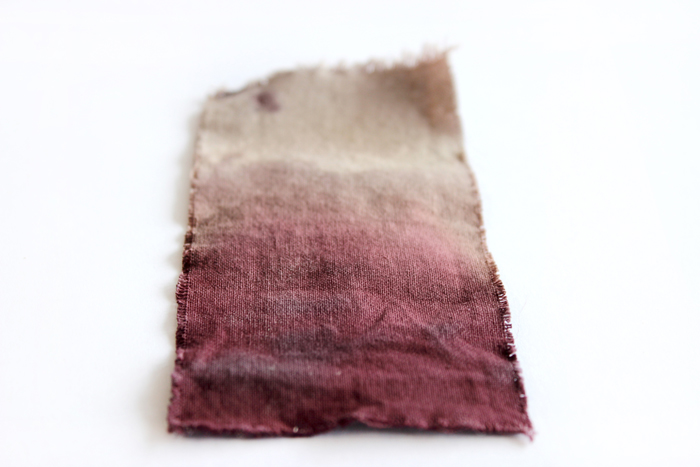

Wine lees colour

To clear my mind, nothing better than a detour in the Provençal scenery of Luberon, during the “Rendez-vous de la couleur”, professional day organised by the Ôkhra ochre conservatory in Roussillon on March the 27th.

A day of conferences full of encounters with artists, painters, colour anthropologists, designers from “Culture couleur”, the French colour committee, unbeatable scientists on prehistoric red, Mayan blue, Indian indigo, or the famous Roussillon ochre. An opportunity to exchange views with these experts on the colouring potentials of wine lees, on pigment extraction techniques, on expectations regarding pigments of the future, on natural dyes, and communicate on the chromatic range of my viticulture materials.

Circular economy in the place of honour

I was expected in Paris on the 2nd of April to attend the Impact2 party, organised by the “Comptoir de l’innovation”, aiming to get projects leaders and investors to meet. The introduction speech from Anne Hidalgo, mayor of Paris, immediately set the tone: social and solidarity economy, collaborative economy and circular economy are on the agenda for the companies of tomorrow. Despite institutional speeches sometimes out of touch with the problems mentioned (global warming, social disparities, environmental challenges) because in my opinion they left too little space for project leaders to put forward their solutions, I especially remember Lionel Zinsou’s speech. This Franco-Beninese economist has been managing since early 2015 the AfricaFrance foundation and detailed the portrait of a creative Africa, naturally building on these economic models whilst composing with its culture and difficulties.

And it is precisely from Africa that I shall write my next column, discovering low-tech processes for R&D on local materials, sources of inspiration for La Termatière.